https://www.hongshencompressor.com/category/products/ammonia-compressor/

The world of NH3 compressors is experiencing a significant change as sectors pursue more efficient and eco-friendly sustainable alternatives for their cooling and cooling requirements. As ammonia is a widely used coolant due to its excellent thermodynamic properties, advancements in compressor technology are crucial to boosting performance, reliability, and sustainability. Looking forward, innovations like the ZW-type and 2V ammonia compressors are revolutionizing the landscape, offering strong options that are poised to satisfy increasing needs.

The ZW ammonia unit, famous for its streamlined design and superior efficiency, is capturing interest as organizations aim to improve their systems. At the same time, the 2V-type ammonia compressor is breaking limits with its state-of-the-art engineering and flexibility, catering to different uses while fostering energy-saving initiatives. Overall, these advancements are establishing the foundation for a fresh chapter in ammonia compressor technology, where efficiency and environmental considerations play a key role in shaping the industry's future.

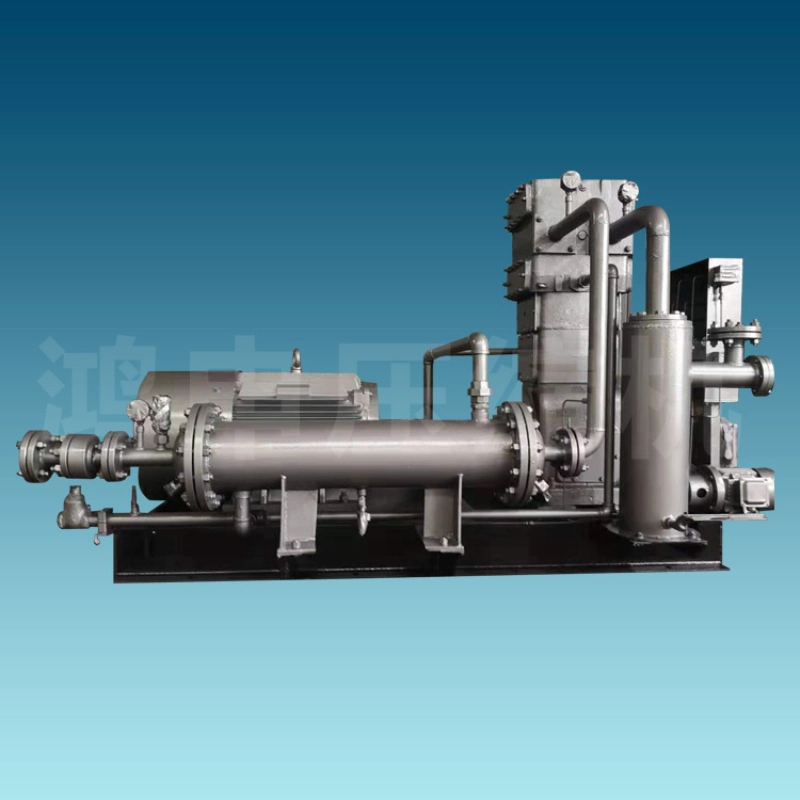

ZW-type ammonia compressor Overview

The ZW-type NH3 compressors is designed to improve the efficiency and functionality of ammonia refrigeration systems. It is characterized by its distinctive design, which allows for high capacity and reliability under different load conditions. This type of compressors is particularly well-suited for large industrial applications, where maintaining a consistent temperature is crucial.

One of the key features of the ZW Type compressor is its capability to handle variable loads while maximizing energy efficiency. The compressors incorporates cutting-edge control systems that modify operating parameters in real-time, ensuring that the system functions at peak performance. Additionally, the ZW-type compressors is built with robust materials that enhance its longevity and reduce service needs, making it a cost-effective solution for businesses.

In the context of sustainability, the Type ZW ammonia compressor supports green practices. As ammonia is a organic refrigerant, its use in these devices helps to reduce the carbon footprint of refrigeration systems. Furthermore, progressive innovations in this technology focus on enhancing energy efficiency and minimizing negative effects on the environment, making the ZW Type compressor a forward-looking choice for the refrigeration industry.

Advantages of two-valve Ammonia Compressor

The 2V-type ammonia compressor offers considerable efficiency gains compared to traditional designs. By utilizing a two-valve system, this compressor minimizes the energy losses typically associated with single-valve configurations. The streamlined operation allows for a higher efficiency compression cycle, which can lead to lower energy consumption and cost savings over time. This efficiency is particularly critical in industrial applications where operational costs are a major concern.

Another advantage of the two-valve compressor is its improved reliability and durability. The design reduces wear and tear on components due to better mechanical balance and minimized vibrations during operation. This extends the lifespan of the compressor, which is a key consideration for facilities relying on constant and consistent ammonia processes. Service intervals can also be extended, allowing for less downtime and improved productivity.

The two-valve configuration also provides better adaptability for multiple ammonia applications. Its flexible design accommodates a range of operating conditions and is suitable for various capacities, making it an optimal choice for industries that require versatility in their refrigeration and heating systems. This adaptability ensures that businesses can implement the technology without substantial modifications to their existing setups, further enhancing its appeal in the market.

Future Trends in Ammonia Compressor Systems

The outlook of ammonia compressor technology appears encouraging, with advancements aimed at boosting effectiveness and minimizing environmental impact. One notable trend is the creation of the ZW series ammonia compressor, which includes a unique configuration aimed at minimizing energy use while maximizing performance. As industries focus on eco-friendliness, developments in this technology are expected to be essential in lowering the environmental impact of ammonia synthesis and chilled processes.

Another important advancement is the introduction of the 2V model ammonia compressor. This configuration focuses on enhancing dependability and adaptive capability, making it well-suited for a wider range of uses. As facilities strive to enhance their ammonia systems for varying loads and conditions, the 2V-type compressor is set to address these requirements, ensuring consistent performance and reduced upkeep expenses.

Moreover, the inclusion of smart technology and IoT capabilities into ammonia compressors is on the rise. Real-time tracking and data-driven insights can improve operational efficiency by enabling anticipatory maintenance and maximized output. This trend not only seeks to minimize inactivity but also assists operators in achieving greater energy efficiency, conforming with global trends toward the digital age and automation in industrial settings.